| CNC 技术参数 | |||||||

| CNC Technical Parameters | |||||||

型号Model | Unit | CNC18 | CNC25 | CNC38 | |||

| 最大弯管能力(>15DR的低碳钢)Maximum bending capacity | mm | Φ18×1.6 | φ25×2.0 | φ38×1.8 | |||

| 圆管/不锈钢管Round tube/stainless steel tube | mm | φ18×0.8 | φ25×1.8 | φ38×1.2 | |||

| 方管/金属Square tube/metal | mm | □15×1.2 | □16×2.5 | □30×1.5 | |||

| 往复送料最大弯管外径(可定制)Maximum bend outer diameter for reciprocating(can be customized) | mm | φ10 | φ25 | φ38 | |||

| 弯曲半径范围Bending radius | mm | 10~80 | 20~100 | 25~150 | |||

| 弯曲半径范围/方管Bending radius range/Square tube | mm | 15~70 | 20~87 | 25~130 | |||

| 弯曲角度范围Bending angle range | degree | 190 | 190 | 190 | |||

| 两层R最大差距R1~R2Two-layer R maximum dfference R1-R2 | mm | 20 | 50 | 50 | |||

| 最大穿心有效距离Maximum effective distance | mm | 1200 | 1500 | 3200 | |||

| 工作台高度(模具中心至地面离度)Workbench height (mold center to ground height) | mm | 1100 | 900 | 1100 | |||

| 模具中心线高度Mold center line height | mm | 22 | 30 | 28 | |||

| 弯曲(B.0.D)速度Bending [D.0.B]Speed | deg/sec | 220 | 220 | 160 | |||

| 弯曲(B.0.D)精度Bending [D.0.B]Sccuracy | degree | ±0.05 | ±0.05 | ±0.05 | |||

| 送料(D.B.B)速度Feeding [D.B.B]Speed | mm/sec | 2000 | 2000 | 1400 | |||

| 送料(D.B.B)精度Feeding [D.B.B.]Accuracy | mm | ±0.05 | ±0.05 | ±0.05 | |||

| 转管(P.0.B)速度Transter tube[P.0.B.]Speed | deg/sec | 300 | 300 | 300 | |||

| 转管(P.0.B)精度Transter tube[P.O.B.]Accuracy | mm | ±0.05 | ±0.05 | ±0.05 | |||

| 油压系统马达Hydraulic system motor | kw | 1.7 | 2.2 | 2.2 | |||

| 机器宽度Machine width | mm | 900 | 900 | 900 | |||

| 机器高度Machine width | mm | 1250 | 1250 | 1300 | |||

| 机器长度Machine length | mm | 2600 | 2900 | 4300 | |||

| 机械重量Machine weight | kg | 900 | 1000 | 28000 | |||

| CNC50 CNC65 | CNC76 | CNC90 CNC110 CNC130 CNC168 CNC219 | CNC273 | ||||

| φ50×2.0 φ65×2.5 | φ75×2.5 | φ89×2.5 φ110×5.0 φ130×5.0 φ168×16.5 φ219×16 | φ270×20.0 | ||||

| φ50×1.3 Φ65×1.6 | φ75×1.9 | φ89×1.5 φ110×2.0 φ130×2.5 φ168×4.0 φ219×14 | φ270×14 | ||||

| □40×1.8 □50×2.3 | □60×2.5 | □75×2.5 □90×2.0 □90×6.0 □110×6.5 □189×14 | □200×14 | ||||

| Φ50 Φ65 | φ70 | Φ70 φ90 Φ114 Φ114 Φ129 | Φ129 | ||||

| 30~230 30~320 | 40~250 | 40~250 50~2800 80~500 90~500 120~800 | 130~1000 | ||||

| 30~190 35~210 | 40~240 | 45~105 50~300 80~430 90~410 120~801 | 130~1000 | ||||

| 190 190 | 190 | 190 190 190 190 190 | 190 | ||||

| 65 75 | 85 | 85 100 130 145 170 | |||||

| 2200 3200 | 4000 | 4000 4000 5000 6000 1400 | 6000 | ||||

| 1100 1100 | 1125 | 1100 1250 1300 1400 1400 | 1400 | ||||

| 40 50 | 55 | 65 80 90 120 165 | 185 | ||||

| 105 100 | 75 | 75 75 70 38 38 | 28 | ||||

| ±0.05 ±0.05 | ±0.05 | ±0.05 ±0.05 ±0.05 ±0.15 ±0.15 | ±0.20 | ||||

| 1400 200~900 | 200~900 | 900 900 900 800 800 | 600 | ||||

| ±0.05 ±0.05 | ±0.05 | ±0.05 ±0.05 ±0.05 ±0.15 ±0.15 | ±0.15 | ||||

| 200 200 | 200 | 200 200 200 90 90 | 90 | ||||

| ±0.05 ±0.05 | ±0.05 | ±0.05 ±0.05 ±0.05 ±0.15 ±0.15 | ±0.20 | ||||

| 3.8 5.5 | 15 22 22 30×2 45×2+11 | 55×2+11 | |||||

| 900 1150 | 1500 | 1500 1700 2000 2200 2300 | 3400 | ||||

| 1300 1400 | 1400 | 1500 2100 2100 2300 2300 | 2700 | ||||

| 4300 5800 | 6800 | 6800 7000 9000 10000 11000 | 11500 | ||||

| 3200 5800 | 7500 | 7900 12000 13000 29000 38000 | 55000 | ||||

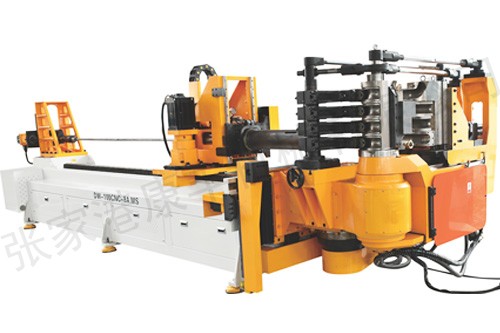

产品特点:

- 通过5-13轴伺服电机精确控制。

- 可实现1-4层模具左弯和右弯功能。

- 可实现大半径或螺旋状产品弯曲、带推弯功能。

- 工业计算机系统具备3D干涉检查功能。

- 可连接机器人和三维测量仪等。

QQ客服

QQ客服